1. Innovation in technical principles

Thixomolding®: Magnesium alloy particles are injected into the mold at high speed in a state of solid (50-60%) and liquid coexistence. The molding temperature is 30% lower than that of traditional die casting, and the grain size is refined to 15μm (50% better than die casting), eliminating pores and thermal cracking defects.

2. Core process advantages

(1) Ultra-high material utilization: Near-net molding technology reduces machining volume, raw material utilization rate reaches 95% (die casting process is only 70%), and unit cost is reduced by 25%.

(2) Extreme lightweight performance: yield strength ≥ 220MPa, elongation > 10%, specific strength 1.8 times that of aluminum alloy, achieving 40% weight reduction of parts.

(3) Micron-level precision control: Tolerance maintained at ±0.05mm (ISO 2768-m standard), surface roughness Ra≤0.8μm, and can be directly PVD coated.

3. Production efficiency breakthrough

(1) Energy-saving manufacturing model: energy consumption is only 40% of the die-casting process (measured ≤1.2kWh/kg), fully enclosed SF6-free protective gas production line, and carbon footprint is reduced by 60%.

(2) High-speed mass production capability: 90-second ultra-short cycle time (including T5 heat treatment), supporting 24/7 continuous production, and annual production capacity of 5 million pieces (single line).

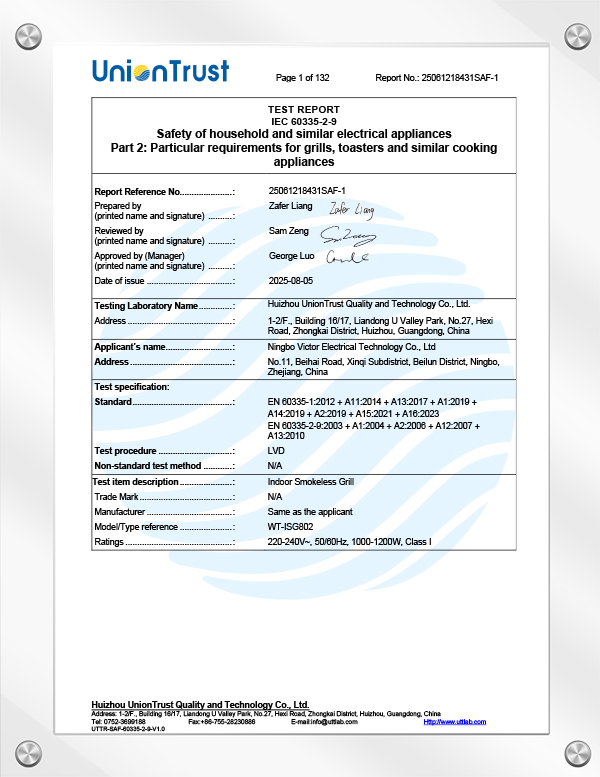

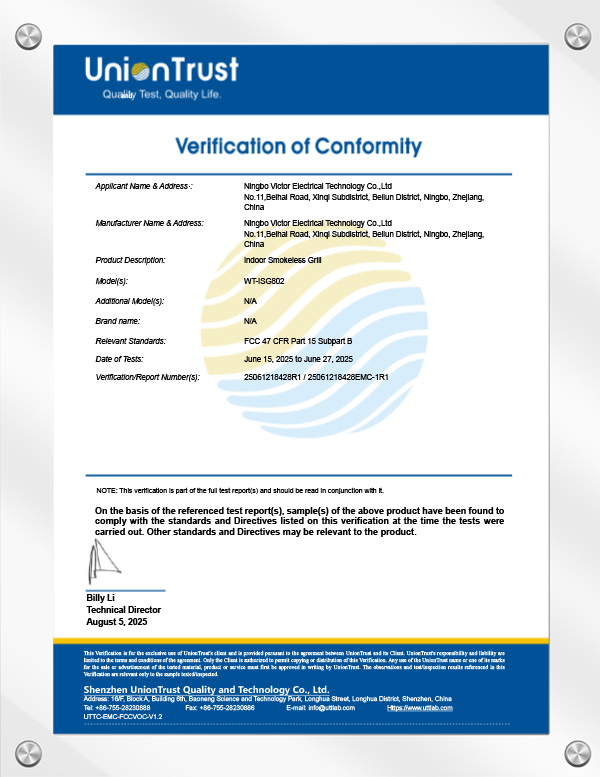

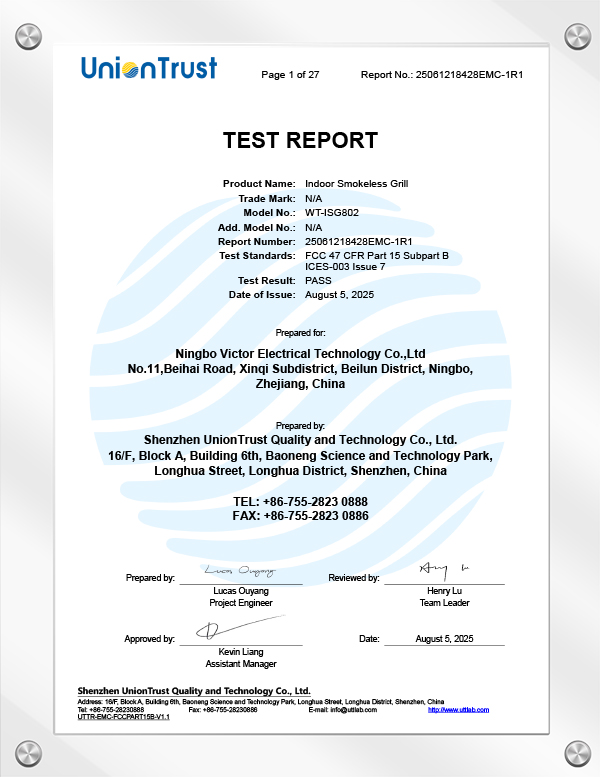

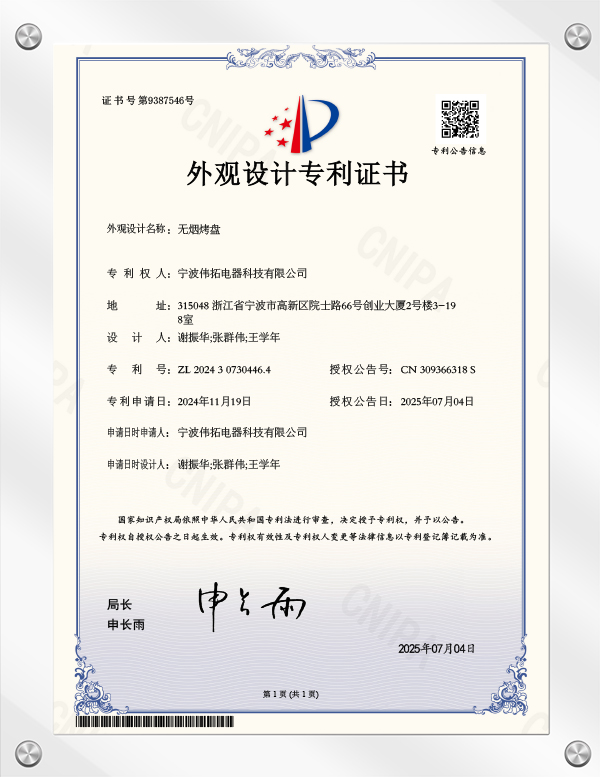

4. Global compliance guarantee

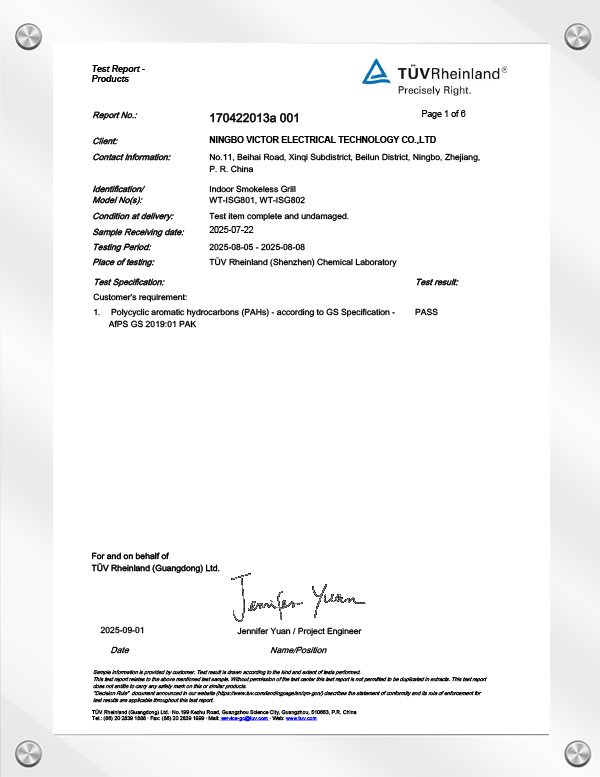

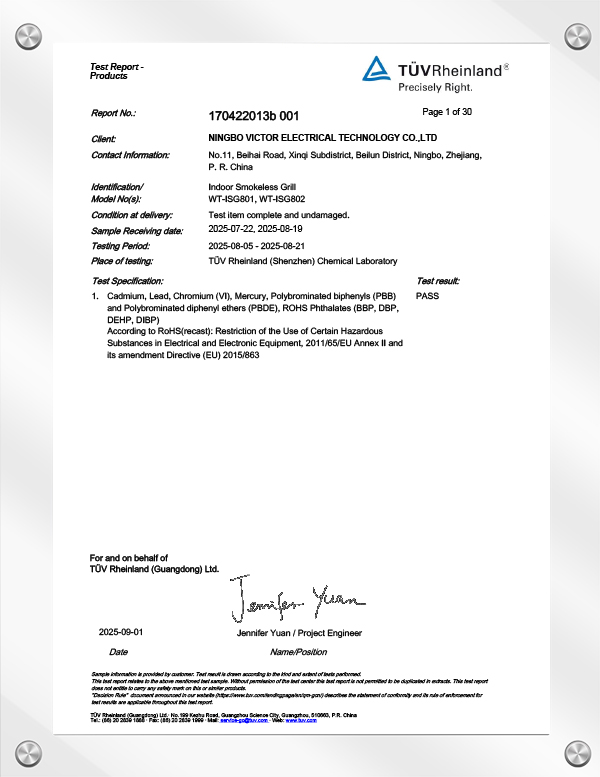

(1) Material safety certification: in compliance with EU REACH Annex XVII cadmium content <0.01%, US ASTM B94-17 standard, and providing IMDS material data sheet.

(2) Process quality control: online X-ray real-time monitoring (generate 3D porosity map for each piece), CPK value stable ≥1.67.

5. Typical application scenarios

(1) Automobile lightweighting: gearbox housing (weight reduction of 3.2kg/piece), steering wheel frame (collision energy absorption increased by 30%)

(2) Consumer electronics: ultra-thin notebook shell (0.6mm wall thickness), drone body (vibration resistance increased by 45%)

(3) Medical devices: MRI equipment bracket (zero magnetic interference), surgical robot joint (2 million times fatigue life)

6. Customized cooperation model

Joint development support: Provide full-process collaboration from material formulation (AZ91D/AM60B customization), mold design (Flow-3D® simulation) to mass production introduction.

中文简体

中文简体 English

English 한국어

한국어 日本語

日本語 русский

русский Español

Español عربى

عربى