Magnesium-Aluminium Alloy Mould And Parts Processing Manufacturers

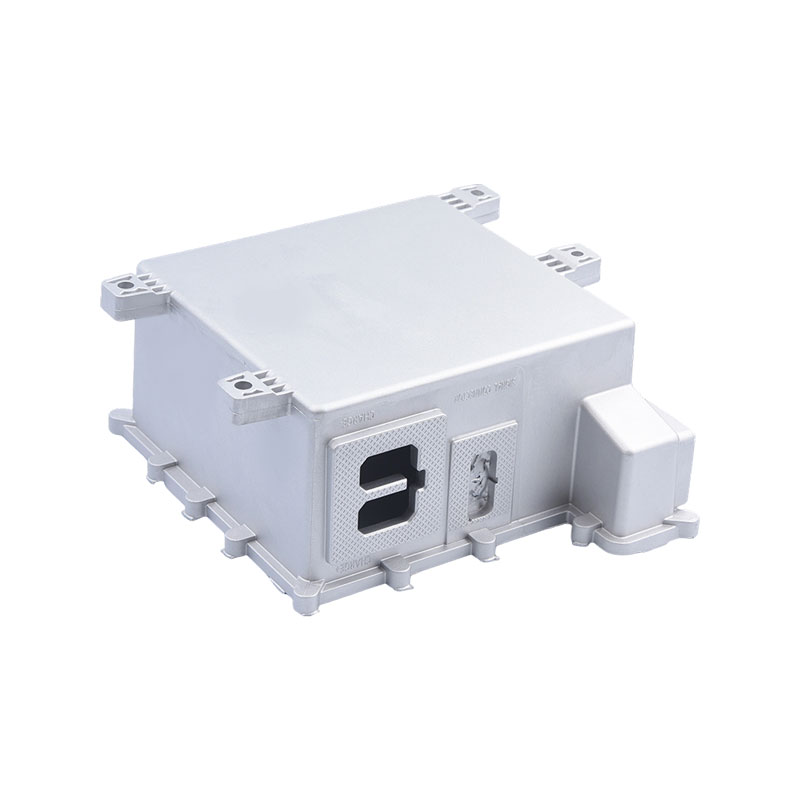

The company has semi-solid magnesium alloy injection molding, aluminum alloy die-casting molding workshops, and small kitchen appliances assembly workshops. Our company respects the corporate spirit of "pragmatic, hardworking, and responsible", and creates a good corporate environment with the business philosophy of honesty, win-win, and innovation. With a new management model and perfect magnesium alloy semi-solid injection molding technology. With our high-level management experience and mature technical strength, we will definitely become your ideal partner. Victor is a professional China OEM Magnesium-Aluminium Alloy Mould And Parts Processing Manufacturers and ODM Magnesium-Aluminium Alloy Mould And Kitchen Appliances Parts Processing Factory, Welcome customers to visit, guide, communicate and cooperate!

The company's corporate culture is: "The enterprise is people-oriented, and employees are proud of the factory". It focuses on cultivating a harmonious atmosphere of unity, friendship, mutual trust, and strengthening group consciousness, so that employees can form a strong cohesion and centripetal force. Employees regard the enterprise as a community of shared destiny and their own work as an important part of achieving common goals. They keep pace with the entire enterprise to form a unified whole and realize common ideals and goals.

-

Compared to traditional charcoal grills, the Smokeless Grill differs significantly in design philosophy and user experience: Combustion Method: Traditional charcoal grills rely on open flames, and inc...

VIEW MORE -

About the Working Principle of the Smokeless Grill The core working principle of the Smokeless Grill lies in "smoke isolation technology" and "smoke and oil recovery technology." Through a special str...

VIEW MORE -

The core working principle of a waffle maker lies in the coordinated operation of its electric heating system and temperature control technology. After being powered on, the heating element inside the...

VIEW MORE -

A waffle maker plate is the core heating and shaping component of a waffle maker. It typically consists of two metal plates with specific raised and recessed patterns. Through high-temperature compres...

VIEW MORE

What key factors should companies consider when selecting a Magnesium-Aluminum Alloy Mold and Parts Processing partner?

1. Technology R&D and Process Maturity

We possess core processes such as semi-solid magnesium alloy injection molding and aluminum alloy die-casting, and are continuously developing material formulations and mold designs.

Industry reports indicate that the integration of material formulation, process parameters, and electromagnetic shielding performance is a key technology for improving the quality of magnesium alloy parts.

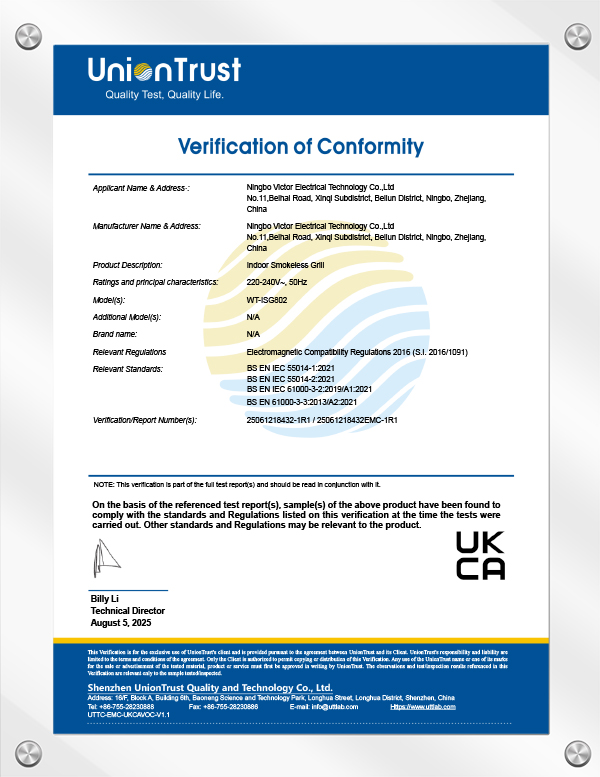

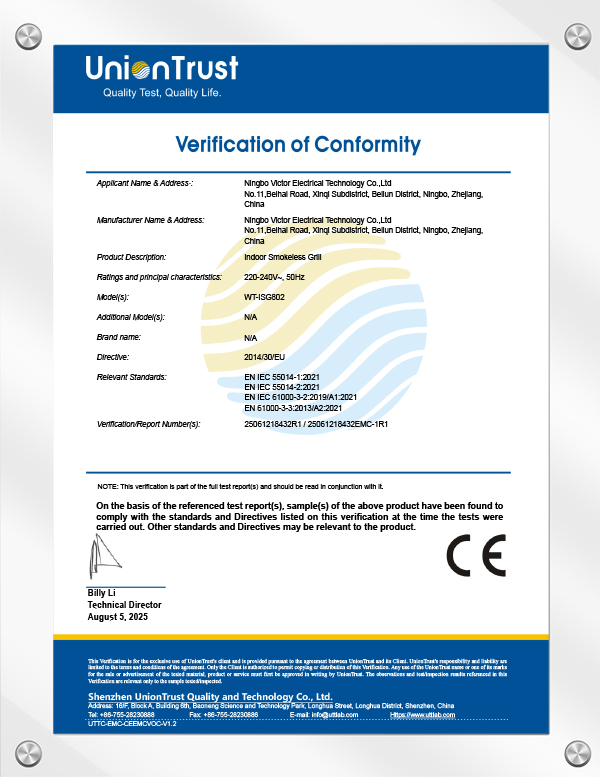

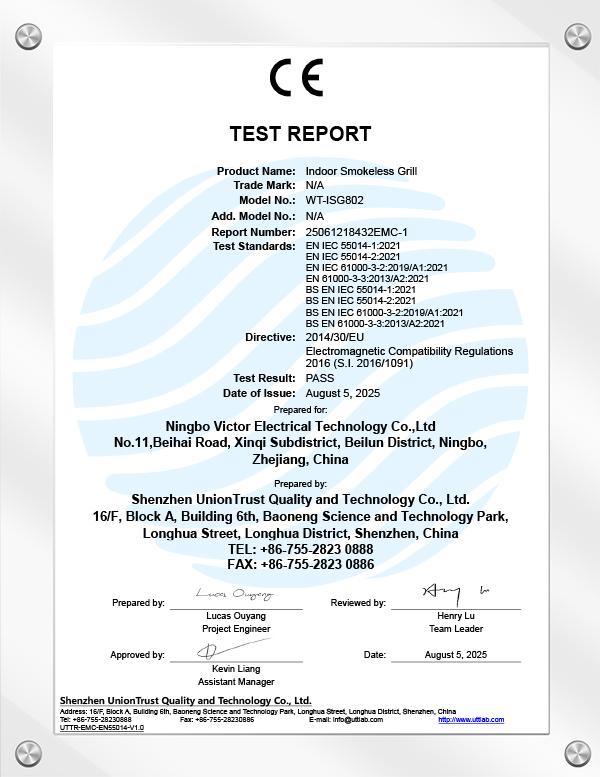

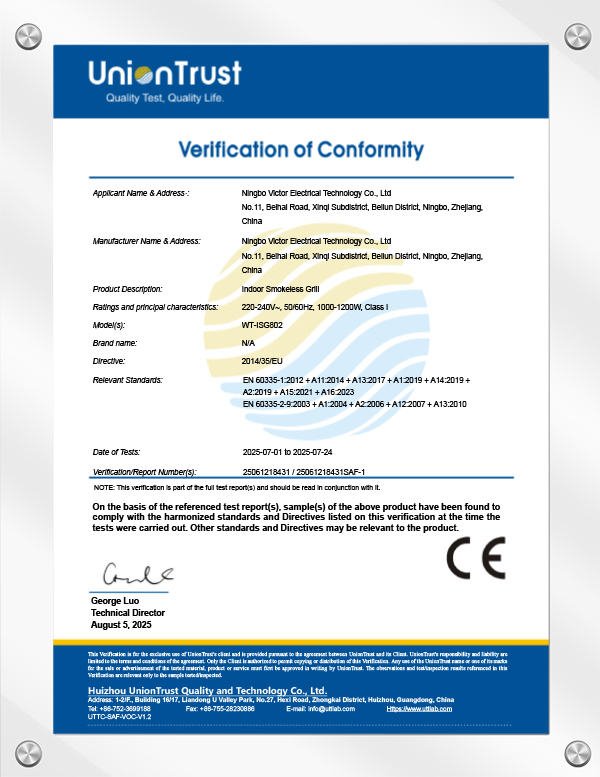

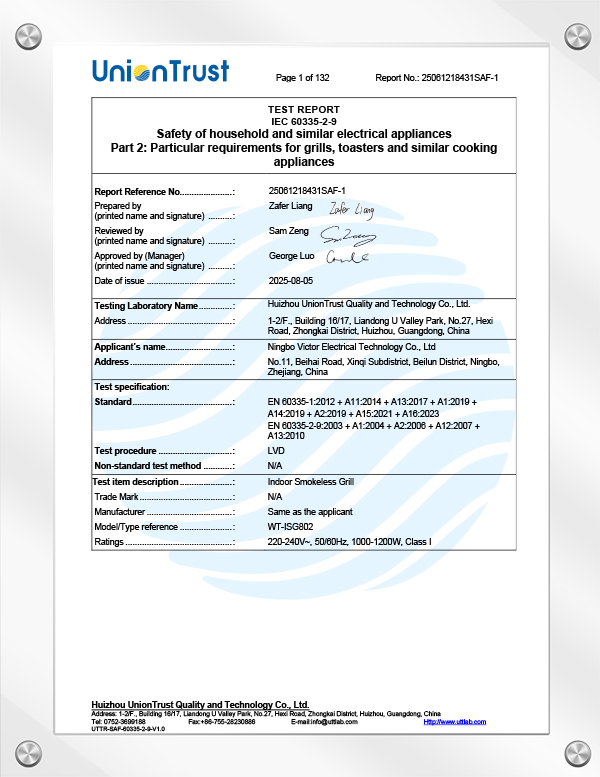

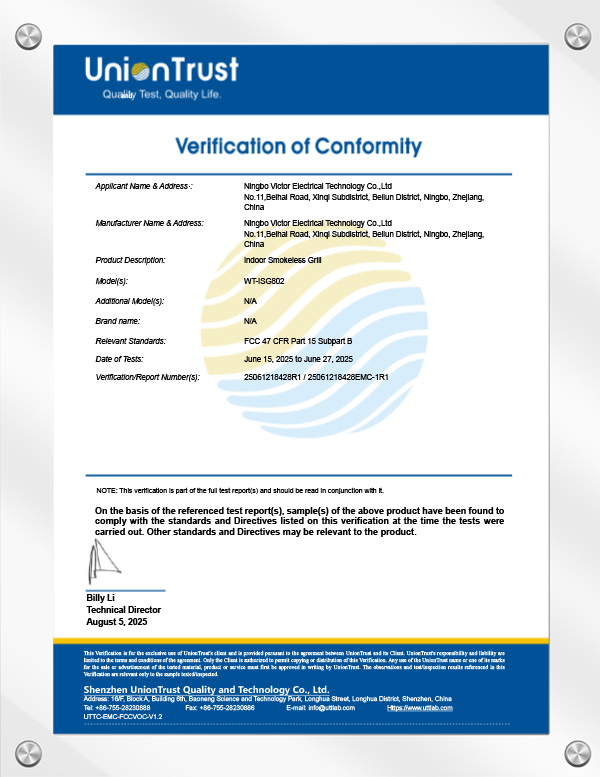

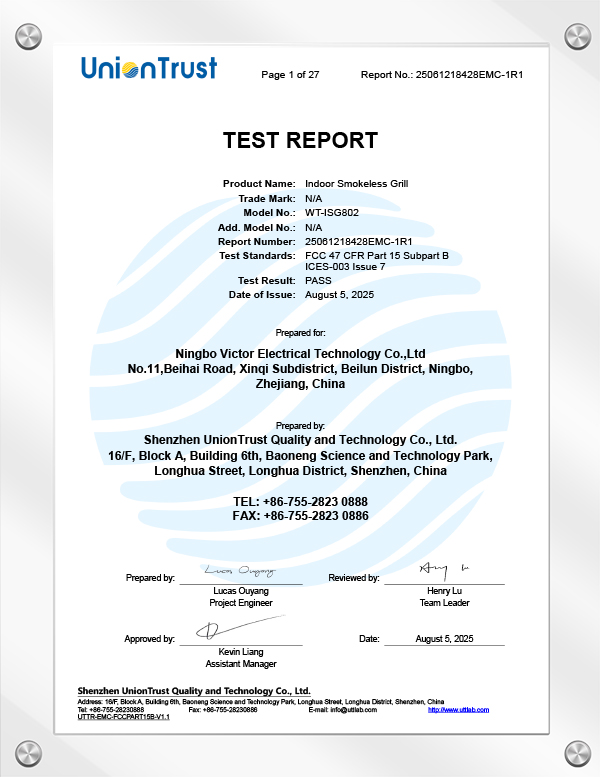

2. Quality Management System and Certifications

With ISO9001 and TS16949 certifications, we enable full-process quality traceability and ensure that product dimensions and mechanical properties meet customer requirements.

3. Production Equipment and Capacity Guarantee

Our modern CNC machining centers, fully automatic die-casting machines, and precision mold processing lines enable fast delivery of small batches and stable supply of large quantities.

Industry-leading CNC machining and die-casting services are considered important factors in selecting a partner.

4. Cost Control and Delivery Capacity

Through lean production and supply chain integration, we reduce material loss and processing costs while ensuring predictable delivery times. 5. Industry Experience and Customer Reputation

With successful cases in various industries, including small appliances, automotive, and aviation, we can provide targeted technical solutions and follow-up services.

What are the core competitive advantages of Ningbo Victor Electrical Technology Co., Ltd.?

1. Complete Industrial Chain Layout

The company boasts a semi-solid magnesium alloy injection molding workshop, an aluminum alloy die-casting workshop, and a small appliance assembly workshop, providing one-stop services from material research and development to finished product assembly.

2. Professional R&D Team and Innovative Management Model

Leveraging mature semi-solid injection molding technology and high-level management experience, we can quickly respond to customer customization needs and provide both ODM and OEM services.

3. Corporate Culture and Team Cohesion

Our corporate culture of "people-oriented, employees take pride in the company" fosters a working atmosphere of unity, mutual trust, and shared progress, improving production efficiency and quality consistency.

4. A Business Philosophy of Integrity and Win-Win Cooperation

Adhering to the business philosophy of "integrity, win-win, and innovation," we prioritize long-term partnerships with our customers and provide technical support, after-sales service, and cost-optimization solutions. 5. Flexible Production Process

Combining Magnesium-Aluminum Alloy Mold and Parts Processing with small appliance assembly, we can complete mold manufacturing, parts processing, and complete machine assembly within the same facility, shortening lead times.

中文简体

中文简体 English

English 한국어

한국어 日本語

日本語 русский

русский Español

Español عربى

عربى