Magnesium Alloy Kitchen Appliances Manufacturers

The company has semi-solid magnesium alloy injection molding, aluminum alloy die-casting molding workshops, and small kitchen appliances assembly workshops. Our company respects the corporate spirit of "pragmatic, hardworking, and responsible", and creates a good corporate environment with the business philosophy of honesty, win-win, and innovation. With a new management model and perfect magnesium alloy semi-solid injection molding technology. With our high-level management experience and mature technical strength, we will definitely become your ideal partner. Victor is a professional China OEM Magnesium Alloy Kitchen Appliances Manufacturers and ODM Magnesium Alloy Kitchen Appliances Factory, Welcome customers to visit, guide, communicate and cooperate!

The company's corporate culture is: "The enterprise is people-oriented, and employees are proud of the factory". It focuses on cultivating a harmonious atmosphere of unity, friendship, mutual trust, and strengthening group consciousness, so that employees can form a strong cohesion and centripetal force. Employees regard the enterprise as a community of shared destiny and their own work as an important part of achieving common goals. They keep pace with the entire enterprise to form a unified whole and realize common ideals and goals.

-

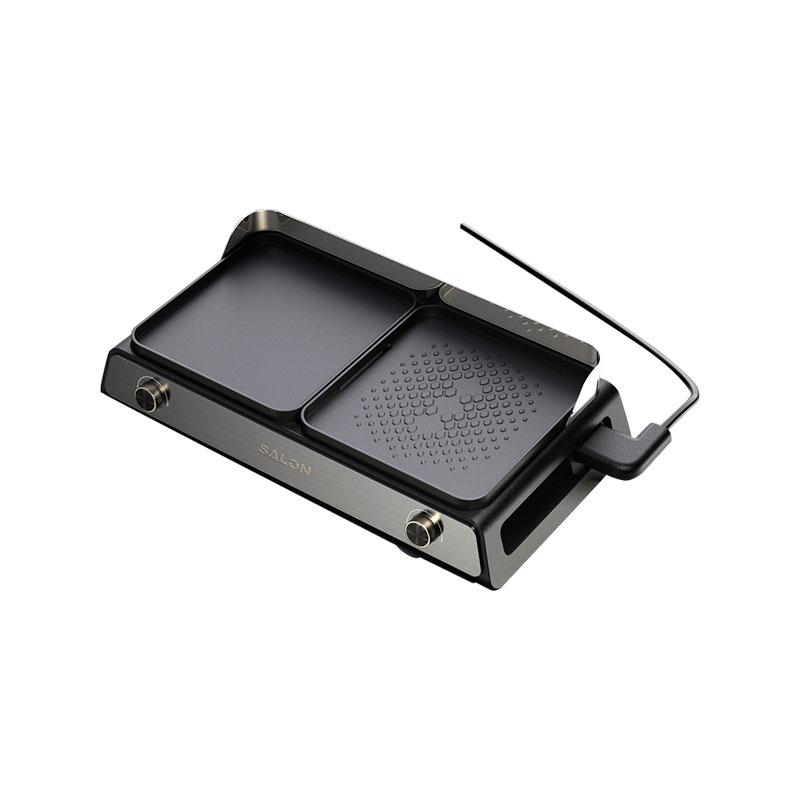

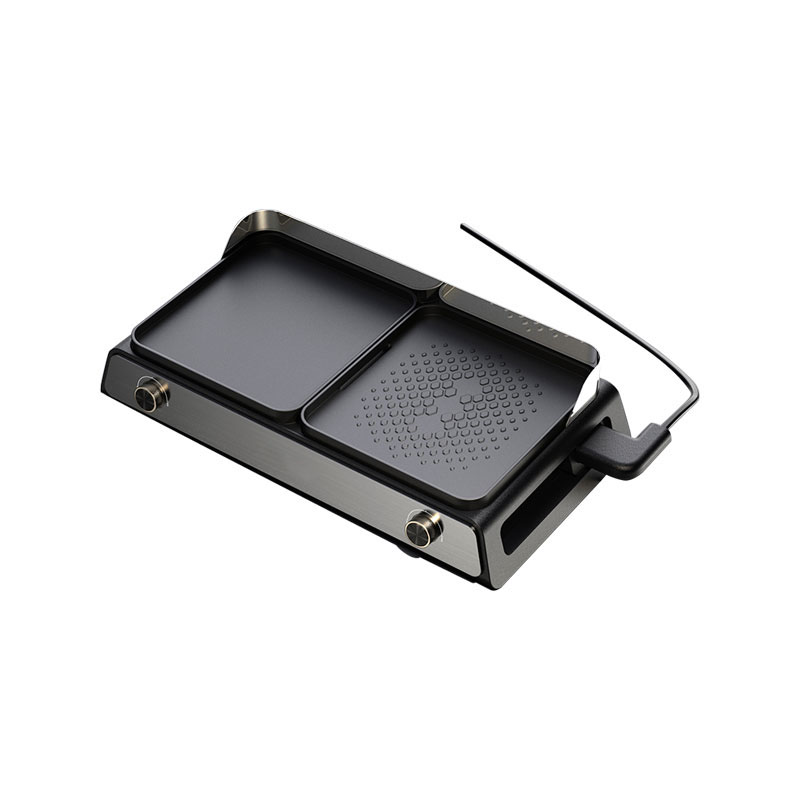

Compared to traditional charcoal grills, the Smokeless Grill differs significantly in design philosophy and user experience: Combustion Method: Traditional charcoal grills rely on open flames, and inc...

VIEW MORE -

About the Working Principle of the Smokeless Grill The core working principle of the Smokeless Grill lies in "smoke isolation technology" and "smoke and oil recovery technology." Through a special str...

VIEW MORE -

The core working principle of a waffle maker lies in the coordinated operation of its electric heating system and temperature control technology. After being powered on, the heating element inside the...

VIEW MORE -

A waffle maker plate is the core heating and shaping component of a waffle maker. It typically consists of two metal plates with specific raised and recessed patterns. Through high-temperature compres...

VIEW MORE

What are the technological advantages of Ningbo Victor Electrical Technology Co., Ltd. in Magnesium Alloy Kitchen Appliances?

1. Semi-solid Magnesium Alloy Injection Molding Technology

Victor utilizes an advanced semi-solid magnesium alloy injection molding process, significantly reducing molding temperatures while maintaining material strength, improving product dimensional accuracy and surface finish. This technology is industry-leading and meets the dual requirements of lightweight and durable high-end kitchen appliances.

2. Efficient Aluminum Alloy Die-Casting Workshop

The company boasts a professional aluminum alloy die-casting workshop equipped with CNC die-casting machines and precision molds, enabling rapid mass production of complex structural components. The high strength and excellent heat dissipation of die-cast parts provide reliable thermal management for Magnesium Alloy Kitchen Appliances.

3. Complete Assembly Line

From raw material processing to finished product assembly, Victor has an integrated production line that ensures end-to-end quality control. The assembly workshop is equipped with automated testing equipment to ensure that every kitchen appliance meets stringent safety and performance standards before leaving the factory.

4. R&D Team and Innovation Capabilities

The company boasts an experienced R&D team that continuously invests in the development of new materials and processes. Leveraging its deep understanding of market demand for Magnesium Alloy Kitchen Appliances, Victor is able to quickly launch innovative, trend-setting products, helping customers seize market opportunities.

How do production capacity and quality control support the delivery of Magnesium Alloy Kitchen Appliances?

1. Multi-Process Parallel Production

By integrating three workshops: semi-solid magnesium alloy injection molding, aluminum alloy die-casting, and small kitchen appliance assembly, Victor is able to simultaneously produce multiple products, significantly improving delivery efficiency.

2. Strict Quality Management System

The company implements the ISO9001 quality management system. All key processes utilize online monitoring and data traceability to ensure that each batch of products meets international standards for dimensions, strength, and surface finish.

3. Flexible Customization

Leveraging its sophisticated mold manufacturing and rapid mold change capabilities, Victor can quickly respond to customers' individual needs and guarantee accurate delivery, whether for small trial runs or large-scale production.

4. Comprehensive Supply Chain Management

We establish long-term partnerships with high-quality domestic and international raw material suppliers to ensure a stable supply of key materials such as magnesium alloys and aluminum alloys, minimizing the impact of raw material fluctuations on production.

中文简体

中文简体 English

English 한국어

한국어 日本語

日本語 русский

русский Español

Español عربى

عربى